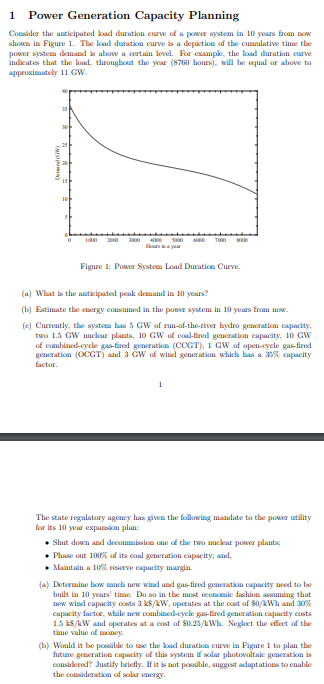

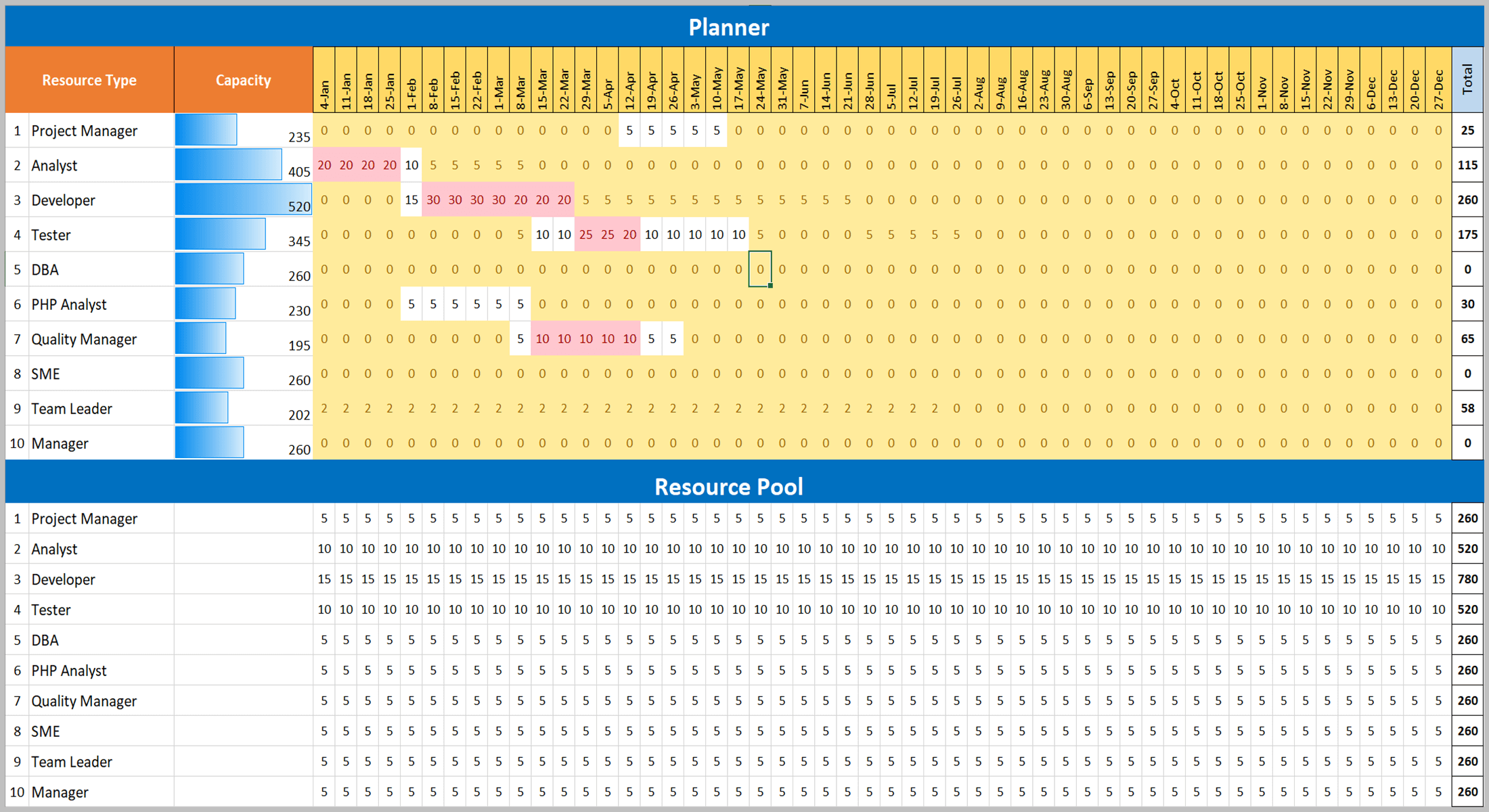

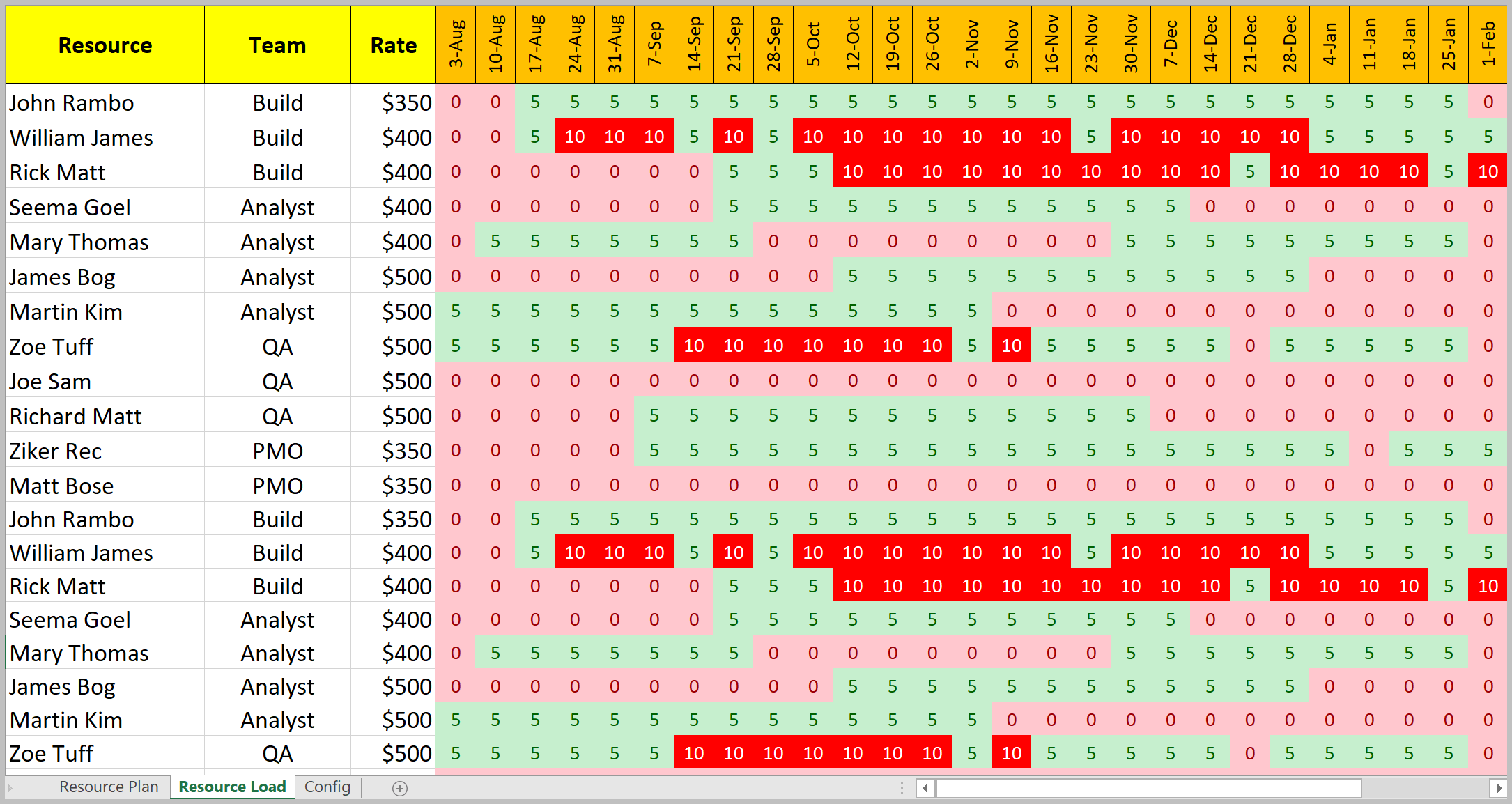

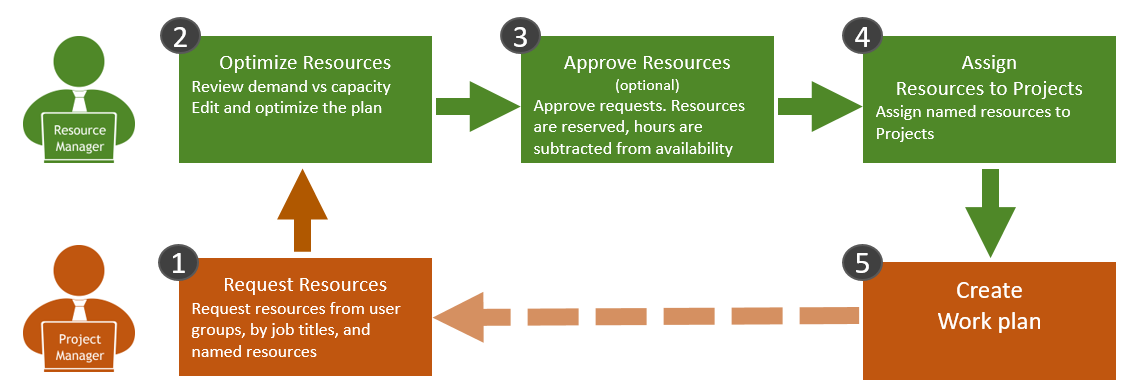

Simply put, if capacity is the means to plan and achieve, then capacity development describes the ways to those means An essential ingredient in the UNDP capacity development approach is transformation For an activity to meet the standard of capacity development as practiced and promoted by UNDP, it must bring about transformation that isThe main point for an organization to plan capacity usage in advance is to match its supply competence and capability levels with the predicted demand by the customer This twin factor of meeting demand and having smooth operations of manufacturing firms can be characterized by adopting capacity strategic options that can enhance capacity utilization (Teemu, 11; To keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by analyzing individual resources Which means for example comparing how many project managers you need for your projects vs how many you currently have Your capacity plan should also look far enough into the future to give you time to recruit and onboard

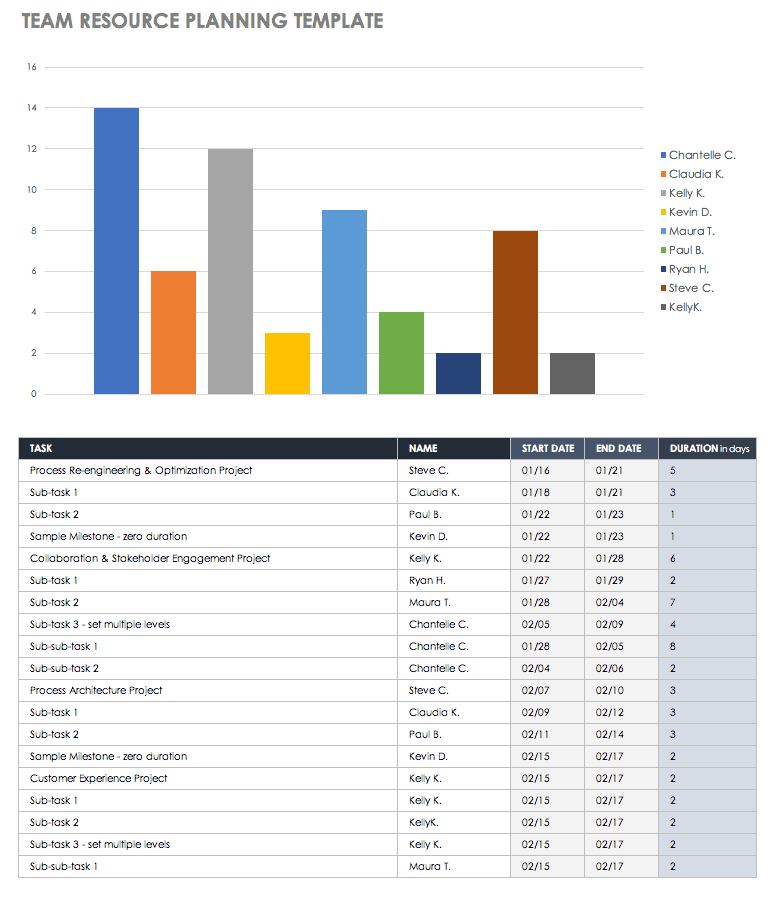

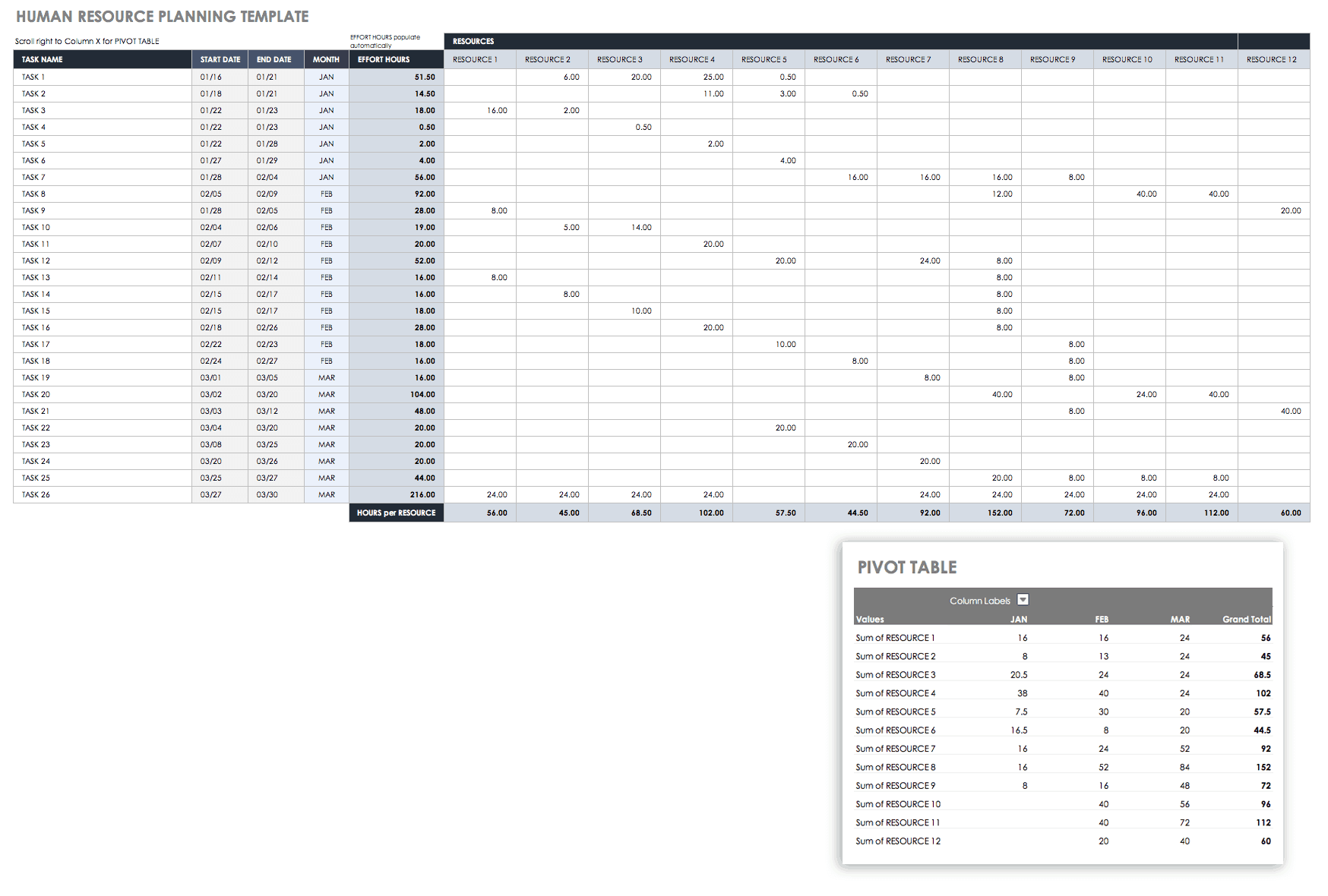

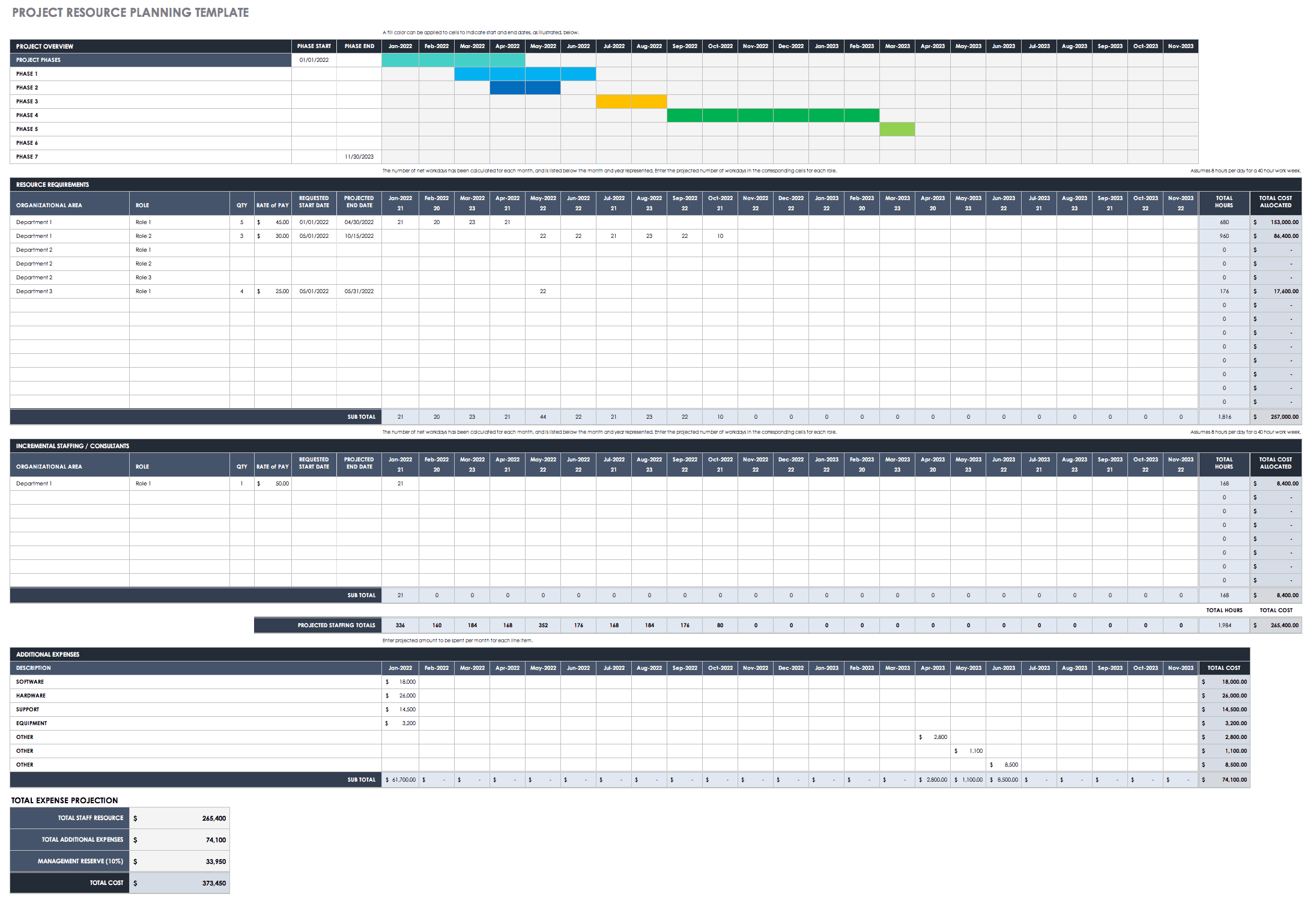

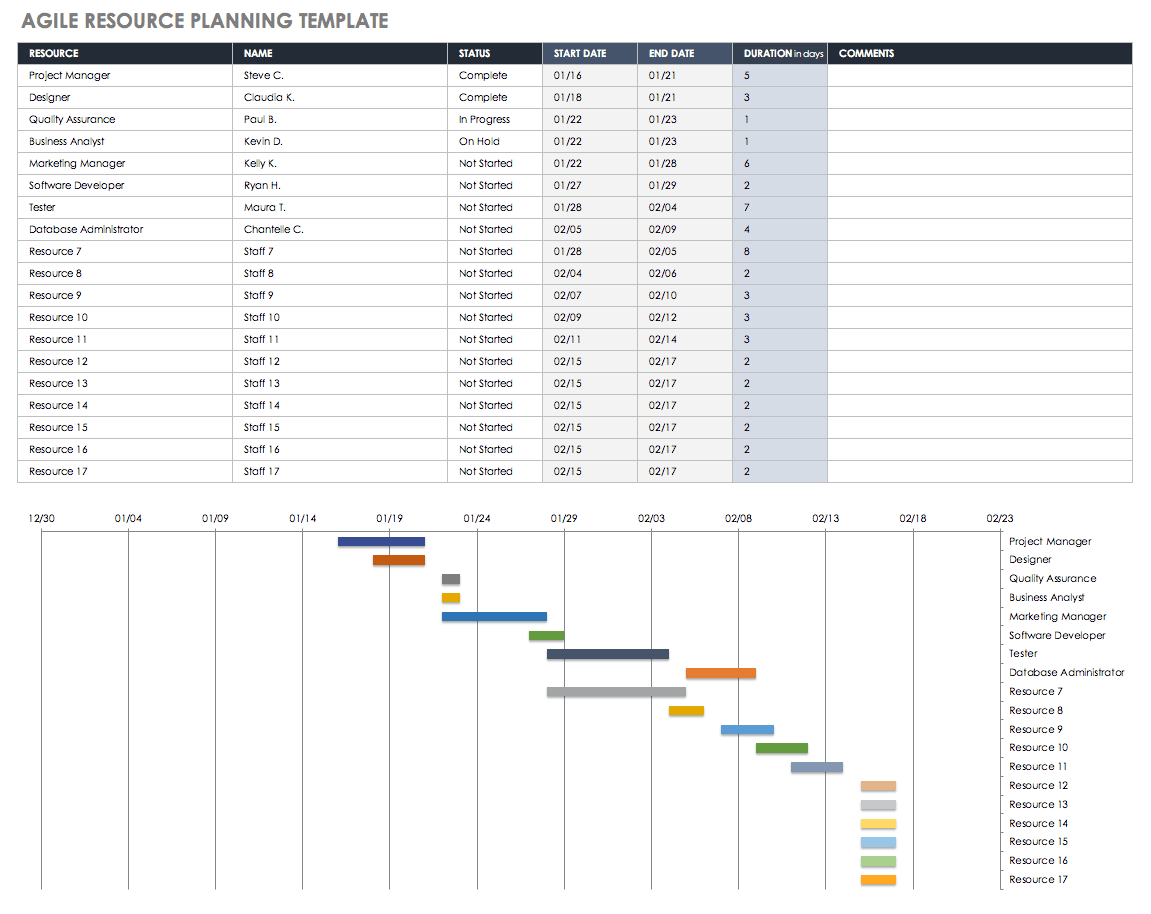

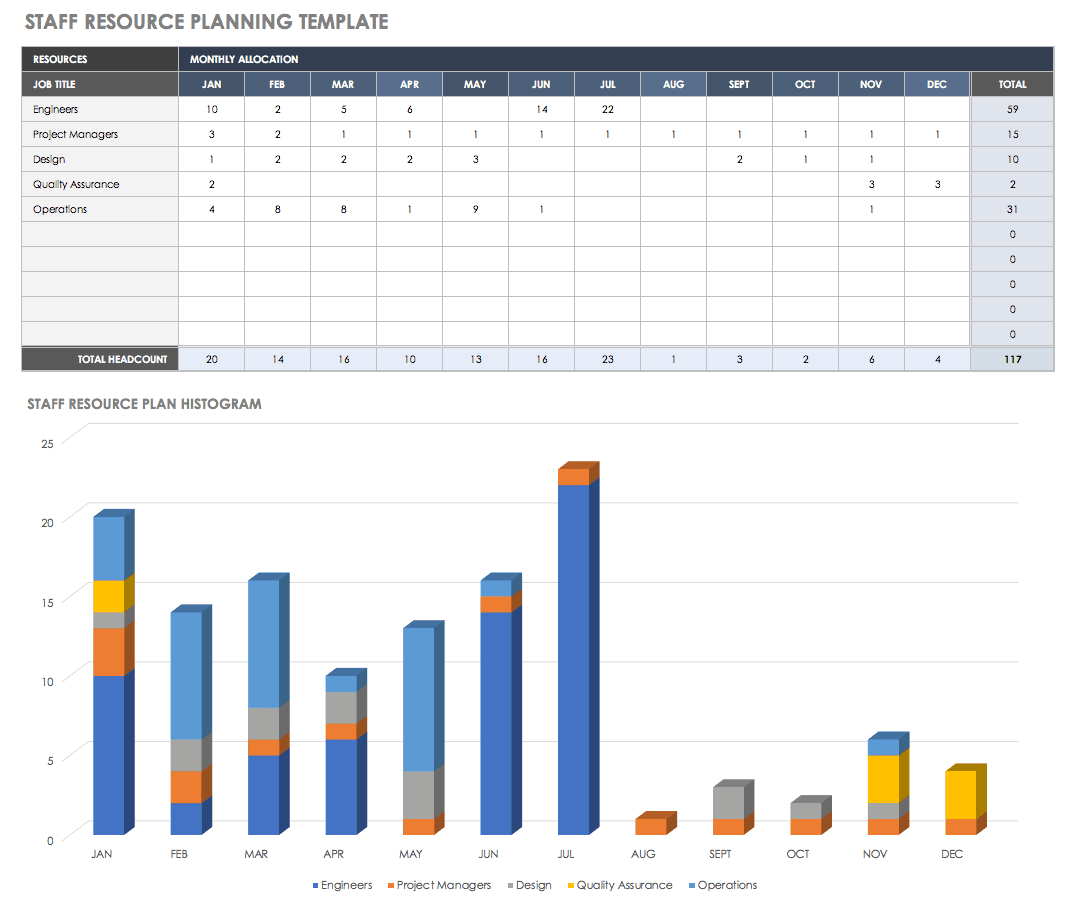

26 Resource Capacity Plan Template Resource Planning Template Human Capacity Project In 21 Action Plan Template Business Letter Template Business Plan Template Free

Level capacity plan example

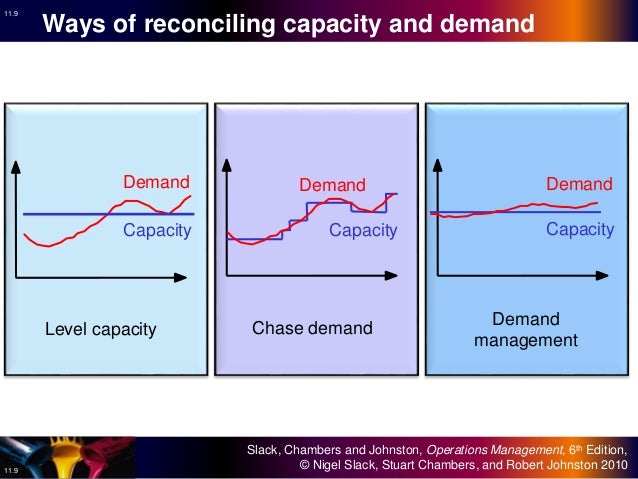

Level capacity plan example-An example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina) In hot countries, salt is produced by allowing the sun to evaporate sea water in shallow pools or 'pans';Sample Capacity Building Plan DRAFT Rev 10 4 Guiding Principles During the Change It is important for Organization ABC personnel to follow these principles as it implements the actions in this Plan 1 Focus on what is needed to change, not on the way it has always been done before 2 There is no blame – focus on plans, policies and

Capacity Plan Template Technical Writing Tools

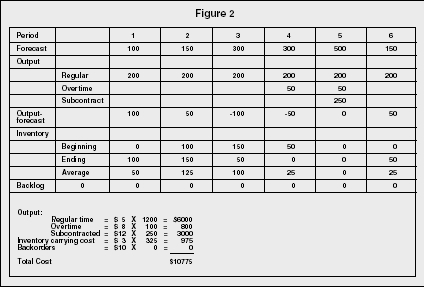

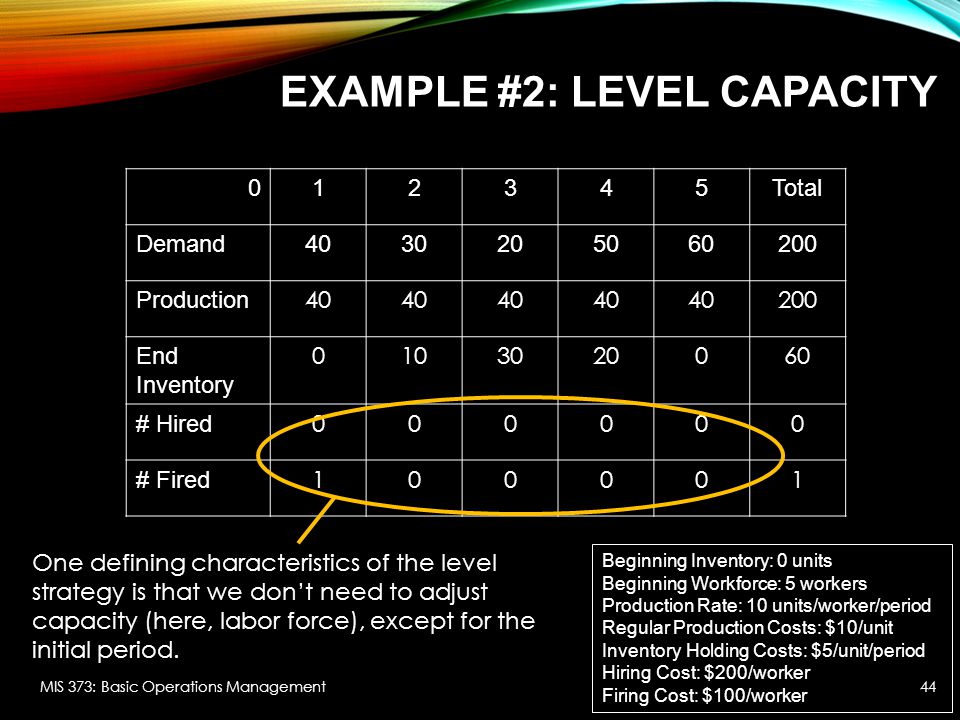

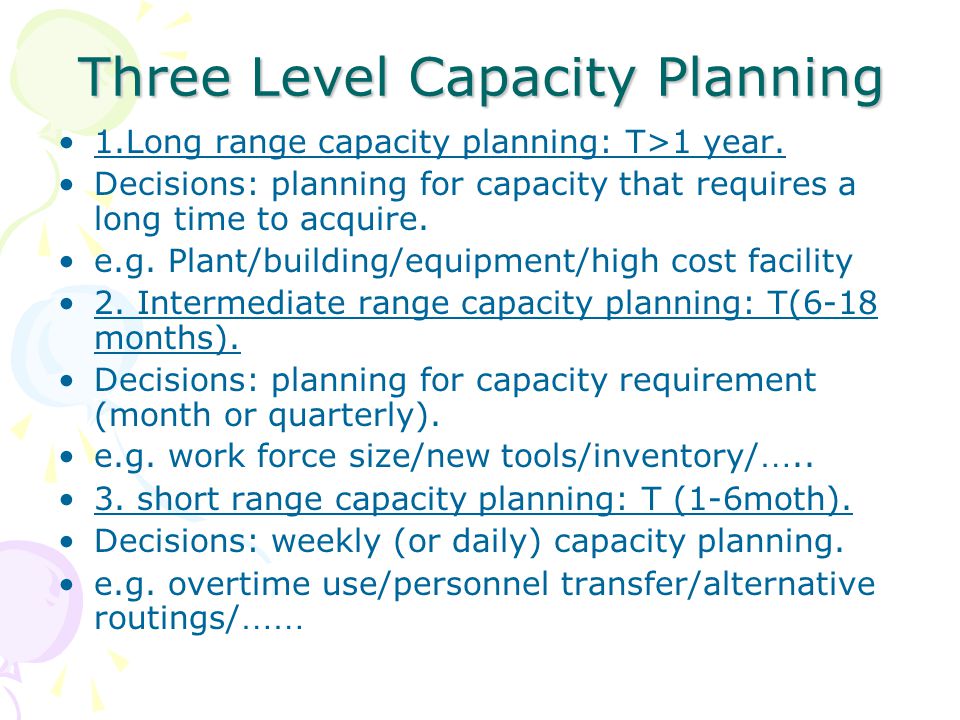

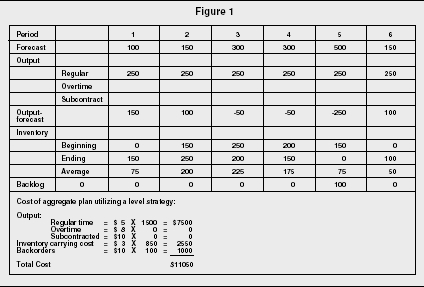

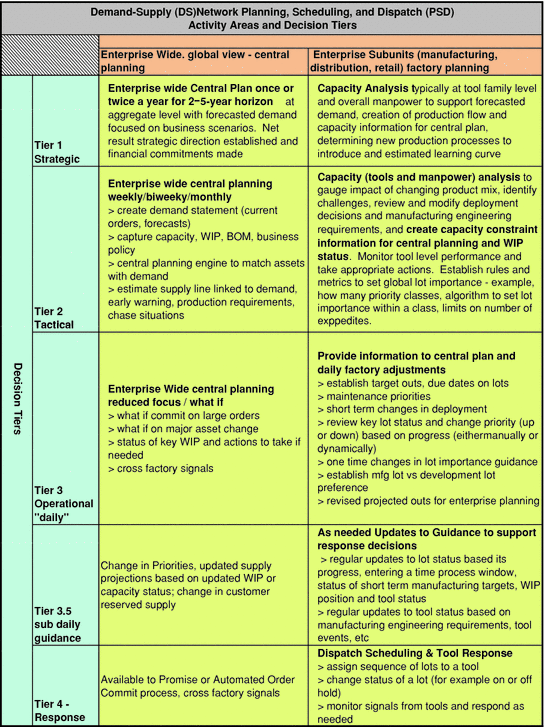

Figure Level Capacity Plan Figure shows the level capacity plan of a company manufacturing a product on produce to stock and sell basis In the first quarter aggregate demand is less than production and inventory builds up till the end of the First Quarters in the second third and fourth quarters are inventory levels Decline because production is less than the aggregate demandThe purpose of this implementation plan is to outline a roadmap for the FDA's resource capacity planning (RCP) and modernized time reporting (MTR) capabilities pursuant to the agency'sExplain about the level capacity strategy Level capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiling or higher holdings of inventory while customer demand levels reduce

Further, the key outcome of using a production capacity template excel spreadsheet is to keep the product inventory to a minimum level even fulfilling the customer demands So, good capacity planning for production results in a positive response to the fluctuation in product demand in different seasons over the product lifecycleConcept of Capacity Planning It means the optimum level of output that can be gotten within a specified period It means the optimum level of output, given the changes in product mix, equipment maintenance, programming and operating issues, labor problems, etc It usually is less than the total design capacity Example if a factory has 100 machines and working hours are 8 hours per day and 26 days per month the efficiency level of operators is observed to be at 80% The production capacity available time per month would be calculated as below o Available monthly production time capacity o 100 machines x 480 Mins x 80 / 100 = Mins / day o Mins x 26

Level capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about the demand of the product He or she may have to use some strategies to meet this uneven and everchanging demand pattern These include pure strategies and strategy which uses a combination of various strategies There What is a level capacity plan?1 Tracking time and level of effort You might be under the impression that completing a task takes 30 minutes, but in reality, it might take up to one and a half hours If this is the case, you're going to need to figure out where the discrepancies are occurring Ask team members how long it takes

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

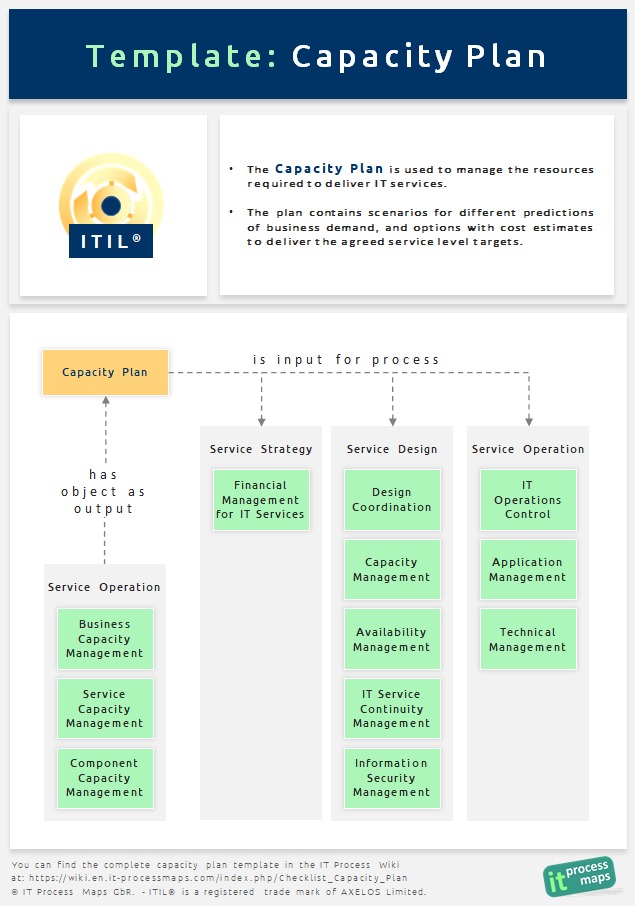

Strategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality It ensures the organization remain competitive and can achieve the longterm growth planI believe that there is a perception that if your company/WFM team has 'a' Capacity Plan, In the example above, the breakeven point for the SL target of 90% of calls answered within 30 seconds – is at 73% occupancy => (73) is the value you would use in our standard CP formula for occupancy This method is a farcry from having an accurate substitute to replace Erlang for intervalDefinition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targets ITIL Process ITIL Service Design Capacity Management Checklist Category ITIL Templates

1 Power Generation Capacity Planning Consider The Chegg Com

1

A period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand What is effective capacity?MPS plan for model A of the previous example ` Maketostock environment ` No safetystock for enditems ⌧I t = I t1 Q t –max{F t,O t} ⌧I t = enditem inventory at the end of week t ⌧Q t = manufactured quantity to be completed in week t ⌧F t = forecast for week t ⌧O t = customer orders to be delivered in week t forecast Ft 1000 1000 1000 1000 00 00 00A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elements that will be required to deliver the output For the operations manager to accept the capacity plan they may need to take into account, materials, machine production time, machine change over time and tooling,

Free Resource Planning Templates Smartsheet

Sap Pp Capacity Planning Cm01 Cm21

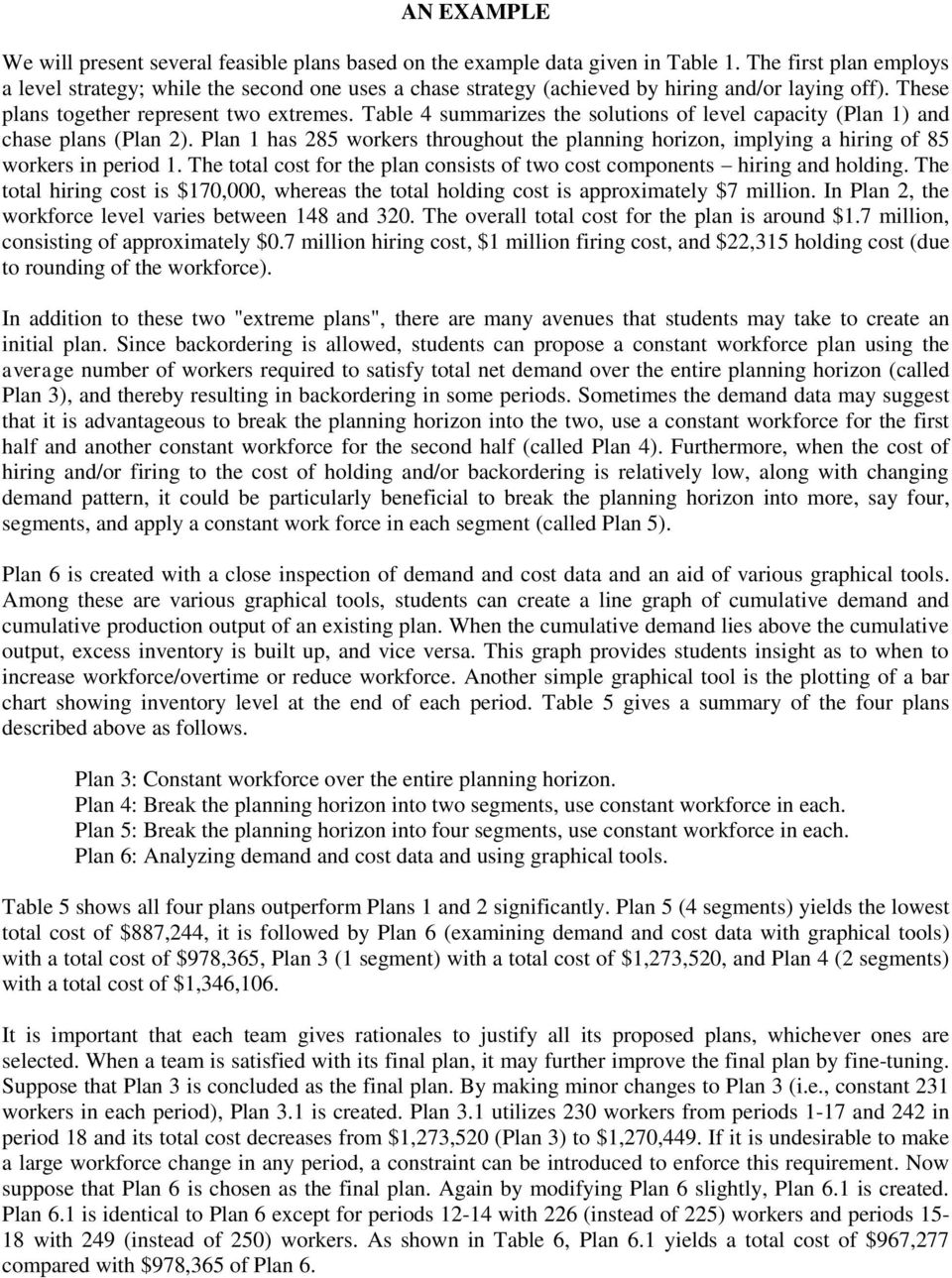

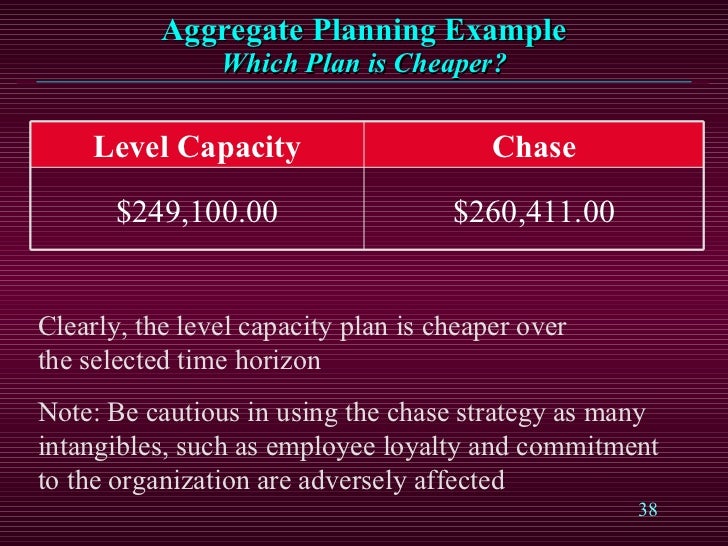

Solution for Level Capacity Production Plan Problem o Manager T C Downs of Plum Engines, a producer of lawn mowers and leaf blowers, must develop an aggregateSee the answer Subway shops are an example of A level capacity plan A pull strategy Vertical integration A fixedposition layout Low visibilityChecklist Capacity Plan Definition The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver theFigure 112 shows the

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Capacity Planning Template Capacity Planning Template Capacity Planning Worksheet for Scrum Teams – Agile CoffeeLevel capacity plan definition Level capacity plan example John Spacey, Capacity management is the process of planning the resources required to meet business demands This includes capacity forecasting, planning, monitoring and performance analysis This can happen at three levels in an organizationAnd the capacity level for each period that maximizes the firm's A solar power plant has production capacity of 30 megawatts based on the equipment such as solar modules that are currently operational at the site Manufacturing A production line has production capacity of 350 units an hour based on the speed of the slowest workstation on the linePlanning and capacity decisions Aggregate plan for production

Capacity Planning And Control Ppt Video Online Download

Match Supply And Demand In Service Industries

Solution for What is level capacity plan?42 Implementing the Action Plan (Monitoring and Supervision) 43 Final Report, Presentation and Evaluation 223 223 223 Appendix 1 Capacity Development Working Group (WG) Terms of Reference (June 10) 2 Organizational Capacity Assessment Sheet (version 2) 3 Individual Capacity Assessment Sheet (version 1 and version 2) 4 Sample of2 Chase capacity management;

Capacity Planning Everything You Need To Know Clicktime

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

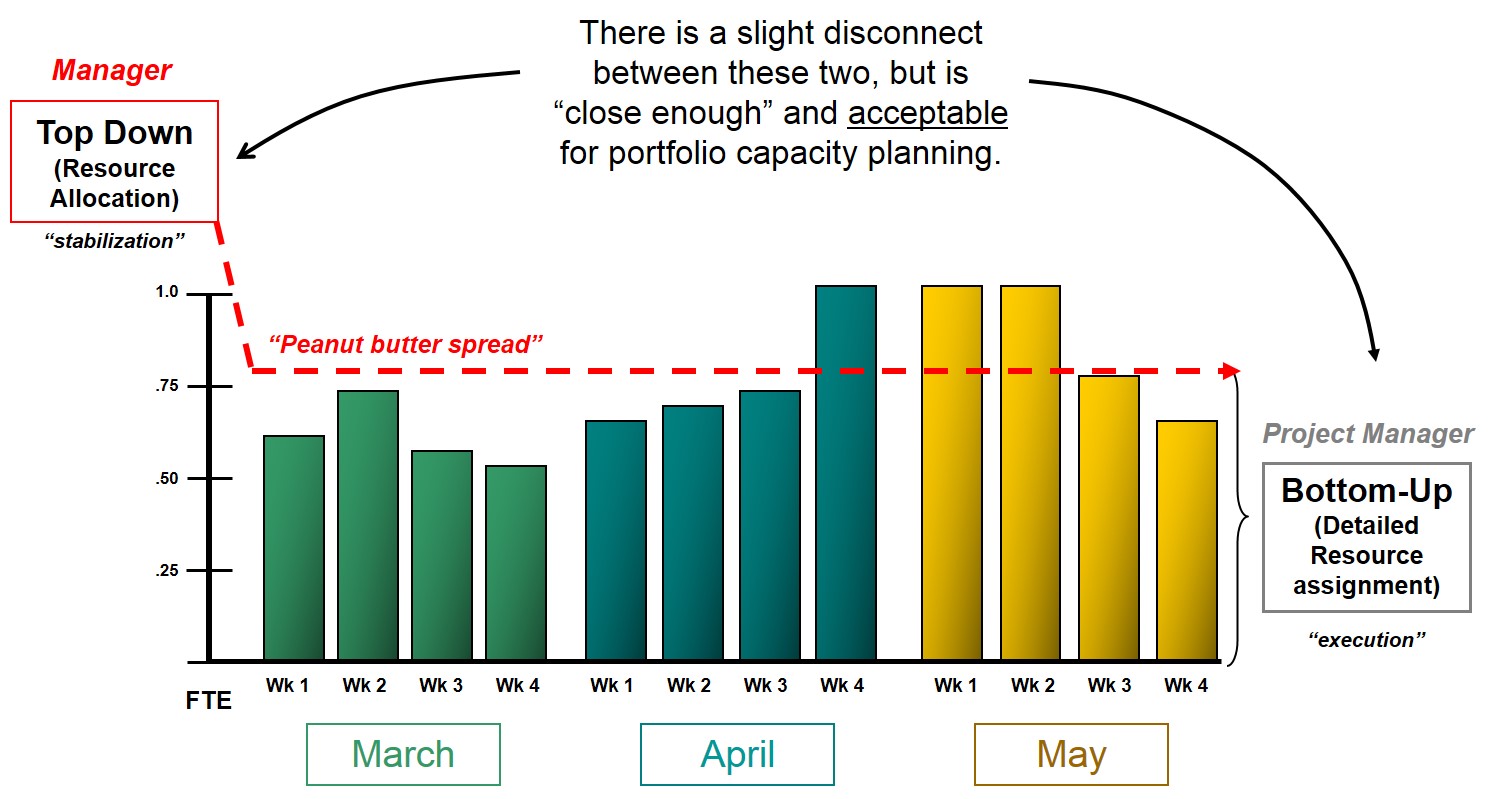

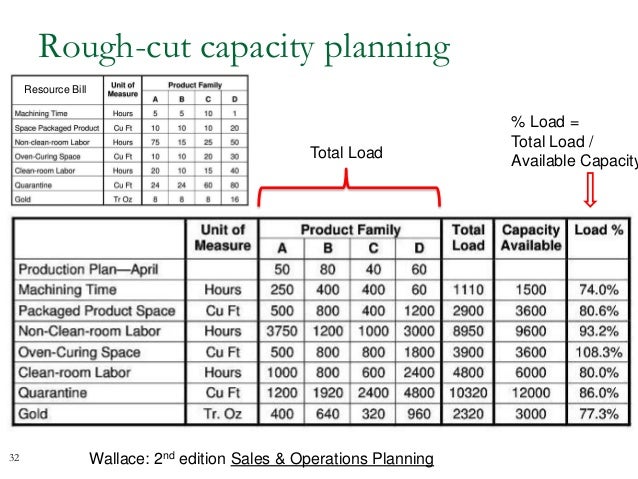

This page is intended to act as an example of what a highlevel capacity plan could look like It is assumed that the organization would build one themselves with some of the below considerations in mind, or would work with Qlik's Services organization Level Production Strategy We are going to find the requirements for the entire period of the plan and also produce the average amount that is needed per month in order to meet the plan First we are going to determine the total average requirements per month Avg requirements = total number of requirements – opening inv closing invThe focus of the plan is to achieve level 1 consistently as a system and to deescalate quickly should pressures arise EMS level 4 should be seen as a "never event" and all actions focused on returning / maintaining EMS level 1 The standard is to have a robust escalation system to support sufficient and safe service capacity across the health and social care system, including

Capacity Utilization Definition Example And Economic Significance

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity, Route Planning, and Scheduling An Efficient Trifecta Once you've got your highlevel (capacity) plan in place, you can use it as a guide for scheduling and route planning You'll want to use all three together to achieve the highest level of logistical efficiency We are here to help with all three From highlevel planning to So, what are the best practices for developing your resource capacity plan?4 Queue design Level Capacity Management "The level capacity plan satisfies high demand from existing stocks When demand goes below capacity, overproduction is stored as inventory in anticipation

Capacity Planning Meaning Classification And Its Goals

Resource And Capacity Excel Plans In 21 Project Management Templates Project Management Tools Capacity Planning

Capacity planning is a longterm strategic decision that establishes a firm's overall level of and customer service is important Utilities, for example, maintain a percent capacity cushion Capitalintensive industries with less flexibility and higher costs maintain cushions under 10 percent Airlines maintain a negative cushionoverbooking is a common practice! 3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacity Strategies The broad classes of capacity planning are lead strategy, lag strategy, match strategy, and adjustment strategy Lead strategy is adding capacity in anticipation of an increase in demand Lead strategy is an aggressive strategy with the goal of luring customers away from the company's competitors by improving the service level and reducing lead time

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

1

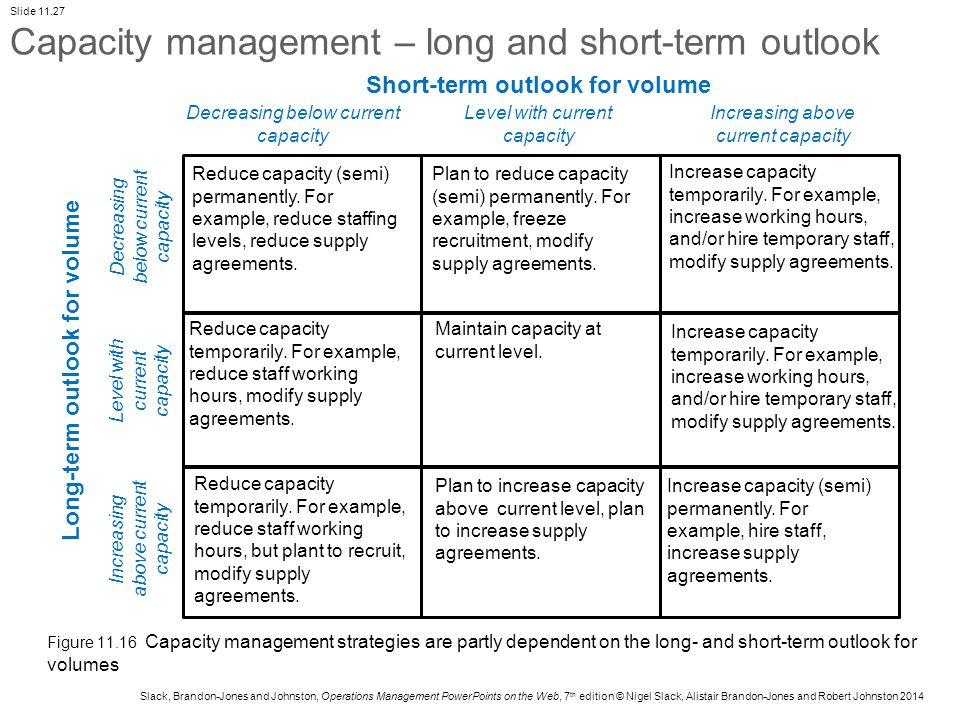

Find extreme or good examples of the following practices and justify the reasons for their adoption 1 Level capacity management;For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands It helps identify and reduce inefficiencies associated with either underutilized resources or unmet customer demand and to10 Annual Sales Plan Examples;An example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina)And the capacity level for each period that maximizes the firm's (supply chain's) profit over the planning horizon – Specify the planning horizon (typically 3 to 18 months) – Specify the duration of each

Capacity Planning And Management 2

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

You may also see annual marketing plan examples Highlevel project planning is closely connected to Agile project management principles, which states that a project manager should oversee the process, which can be described as a facilitative way of leadership You may also see restaurant event proposal examples In this case, facilitative leadership means that PMs point√画像をダウンロード level capacity plan definition Level capacity plan example A definition of business capacity with examples Business capacity is the volume of work that can be handled by an organization, team, process, service or tool It can often be scaled up and down by adding, reallocating and subtracting resources ANS A level production strategy plans for the 16 Level Capacity Strategy Capacity (production rate) is held level (constant) over the planning horizon The difference between the constant production rate and the demand rate is made up (buffered) by inventory, backlog, overtime, parttime labor and/or subcontracting 17 17 Developing and Evaluating the Level Production Plan Assume that the amount produced each

Capacity Plan Template Technical Writing Tools

Excel Based Resource Plan Template Free Download Project Management Templates

3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can beIntroduce the document by providing a highlevel summary of this plan, highlighting the main issues, options, recommendations, and costs You can also provide a brief background of the following items Your company's current levels of capacity Current problems or anticipated issues due to lack of capacity Degree to which the service levels (SLAs) are being achieved 11 PurposeCapacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40

Capacity Plan Template Ms Office Templates Forms Checklists For Ms Office And Apple Iwork

Capacity Planning An Overview Sciencedirect Topics

Capacity Plan Template Word Templates For Free Download

Capacity Plan Template Technical Writing Tools

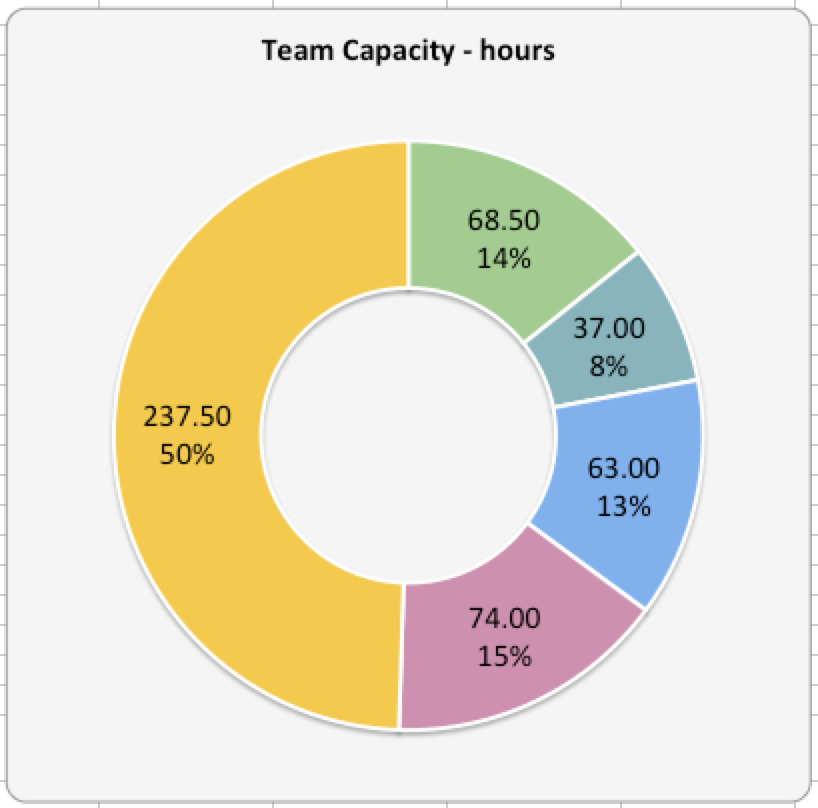

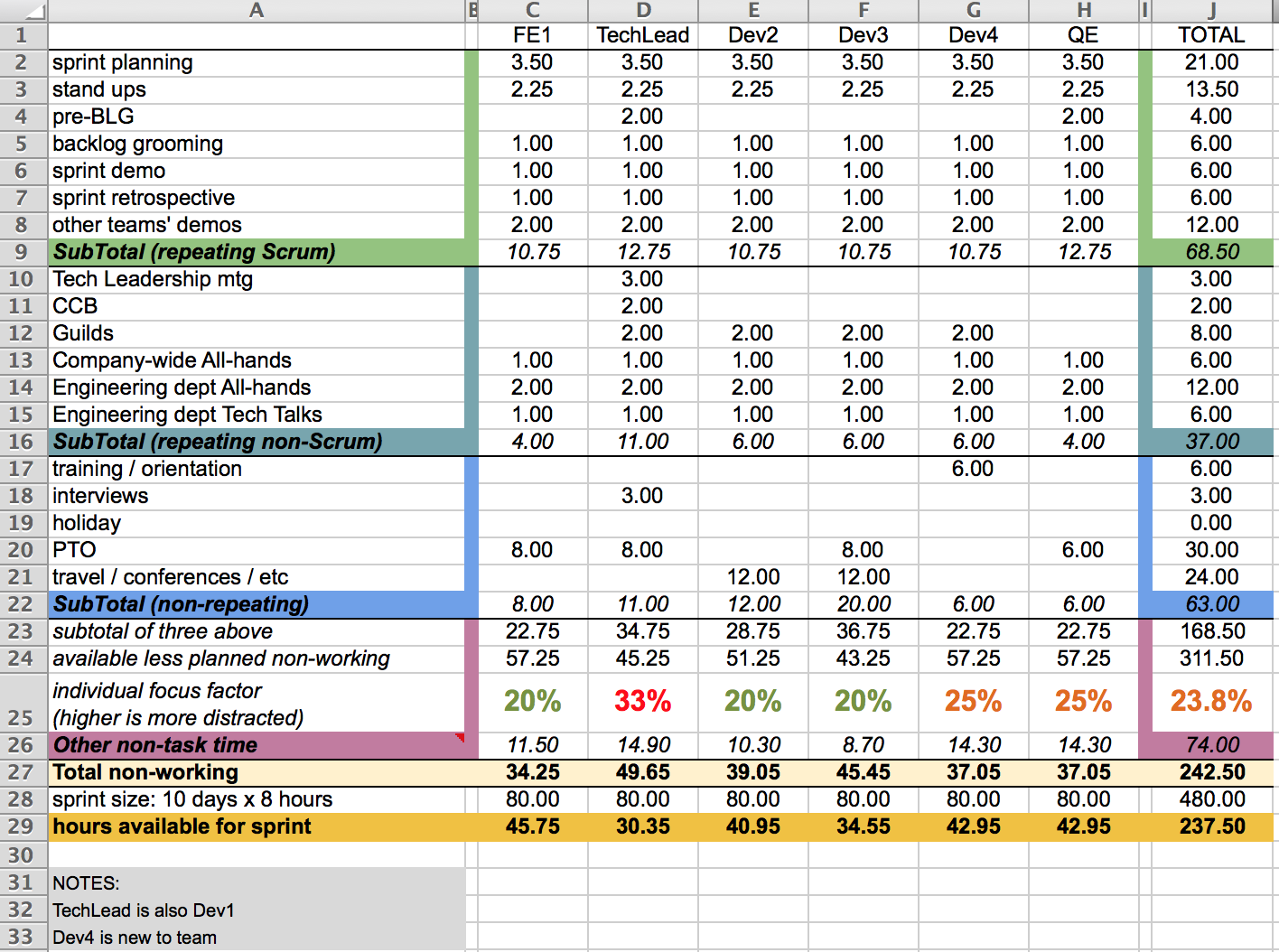

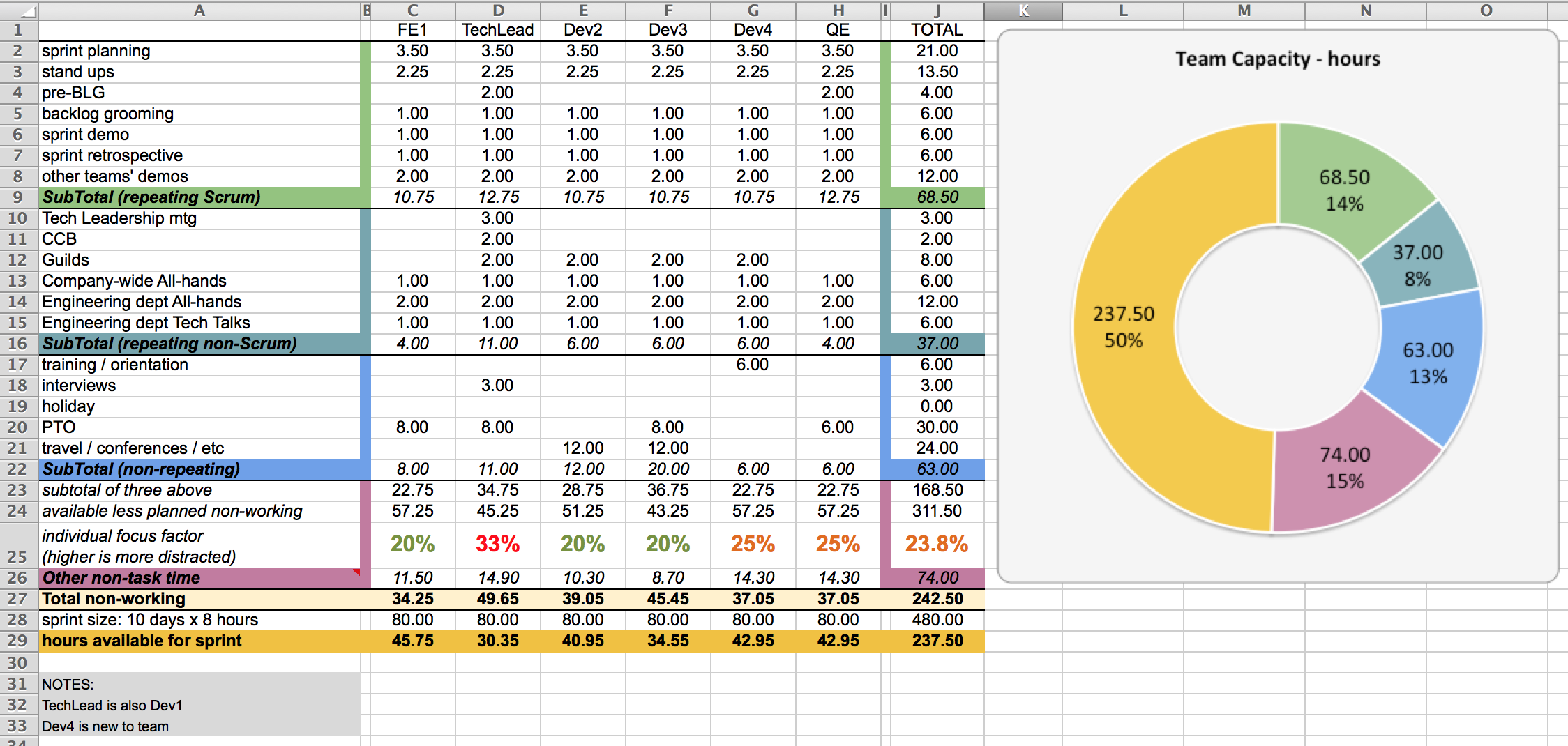

Capacity Planning Worksheet For Scrum Teams Agile Coffee

Workclout 3 Case Studies Examples Of Capacity Planning

Capacity Planning 3 Methods How To Implement Them Optimoroute

Study Of Manufacturing System Capacity Planning Control Steps In Capacity Planning Measuring Demand Capacity Yield Management

Capacity Planning 3 Methods How To Implement Them Optimoroute

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

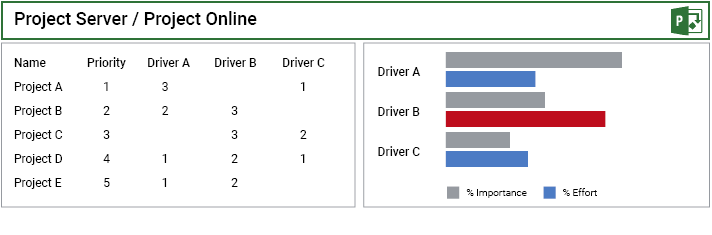

Manage Resource Capacity Planning Scenarios

Production Planning Meaning Importance Steps Example Mba Skool

Capacity Planning Worksheet For Scrum Teams Agile Coffee

7 1 Capacity Planning Saylor Bus300 Operations Management

Long Rang Capacity Planning Ppt Download

The Goal Of Resource Capacity Management

The Itil Capacity Plan Is Used To Manage The Resources Required To Deliver It Services Capacity Planning How To Plan Templates

Teaching Aggregate Planning In An Operations Management Course Pdf Free Download

Capacity Plan Template Ms Word Templates Forms Checklists For Ms Office And Apple Iwork

Chapter 3 Strategic Capacity Management Ppt Video Online Download

Sap Pp Capacity Planning Cm01 Cm21

Capacity Plan Template Technical Writing Tools

Capacity Planning Example

Sap Pp Capacity Planning Cm01 Cm21

1

Resource And Capacity Management

Free Resource Planning Templates Smartsheet

Capacity Planning Model The Important Inputs Formulas And Benefits Semantic Scholar

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Capacity Planning And Control

Capacity Planning Template Clicktime

Capacity Planning Process 4 Overall Capacity Planning Process The Download Scientific Diagram

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

26 Resource Capacity Plan Template Resource Planning Template Human Capacity Project In 21 Action Plan Template Business Letter Template Business Plan Template Free

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Capacity Planning Template Free Download

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

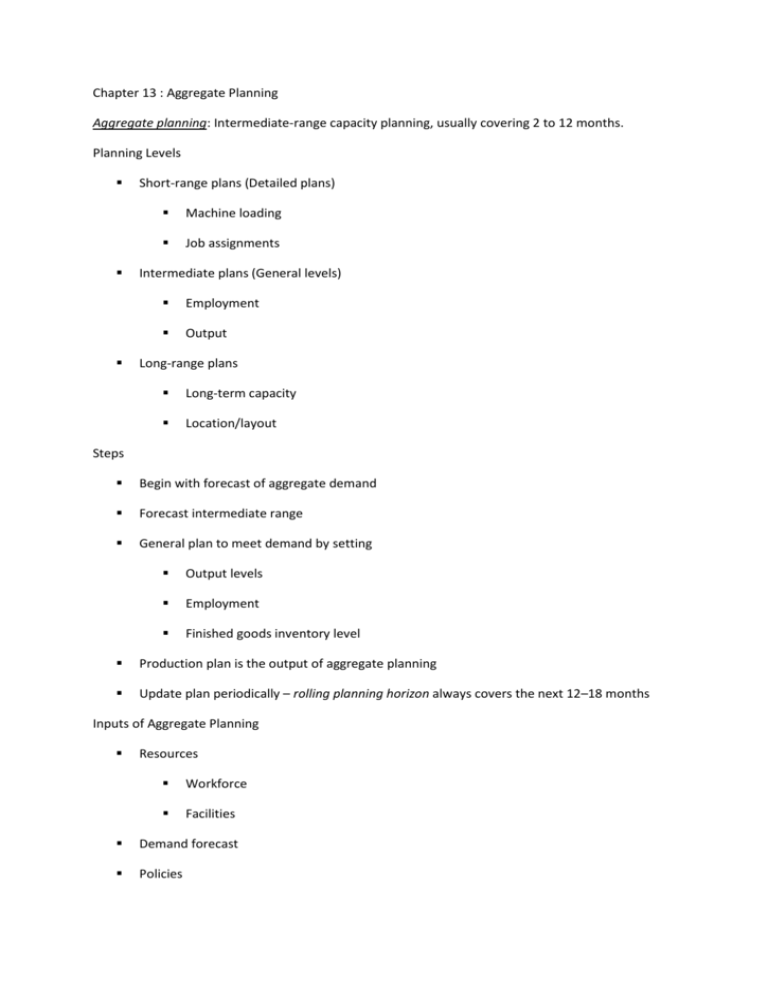

Chapter 13 Aggregate Planning

Resource And Capacity Management

Chapter 11 Capacity Management Ppt Video Online Download

Capacity Planning Everything You Need To Know Clicktime

Entries For Thursday 25 October 07 Sergio S Blog

Capacity Plan Template Ms Office Templates Forms Checklists For Ms Office And Apple Iwork

Capacity Utilization Manufacturing Kpi Examples Sisense

Capacity Planning 3 Methods How To Implement Them Optimoroute

Sales Amp Operations Planning

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Resource And Capacity Management

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

1

Capacity Planning Example

Capacity Planning 3 Methods How To Implement Them Optimoroute

Klauuuudia Itil Capacity Plan Template

Excel Based Resource Plan Template Free Download Project Management Templates

Checklist Capacity Plan It Process Wiki

Capacity Plan Template Word Templates For Free Download

How To Calculate Production Capacity Of A Factory

Checklist Capacity Plan It Process Wiki

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Planning Worksheet For Scrum Teams Agile Coffee

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Capacity Planning And Control Chapter 11 What Is

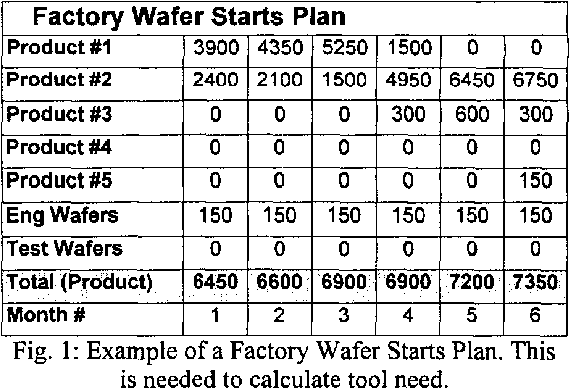

The Ongoing Challenge For A Responsive Demand Supply Network The Final Frontier Controlling The Factory Springerlink

11 Capacity Planning And Control Operations Management

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

A Critical Insight To Successful Supply Chain Planning

23 It Quality Stuff Ideas Process Map Technology Infrastructure Change Management

Iteration Planning Scaled Agile Framework

Capacity Planning Everything You Need To Know Opensense Labs

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Production And Operations Management Systems Chapter 4 Capacity

Free Resource Planning Templates Smartsheet

Dennis Adams Associates Management And Infrastructure Sig Meeting

Free Resource Planning Templates Smartsheet

How To Do Capacity Planning Youtube

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Free Resource Planning Templates Smartsheet

Capacity Planning Template Clicktime

Capacity Planning 3 Methods How To Implement Them Optimoroute

0 件のコメント:

コメントを投稿